Every Bonderkage product is engineered within a layered protection system, where each component works together as a unified whole.

The foundation of the system

Base Layer

The foundation of the system, engineered to manage moisture, regulate temperature, and support natural movement without restricting performance.

Designed to feel invisible while working constantly maintaining comfort, stability, and breathability throughout every shift, practice, and game situation.

Certified protection where it matters most

Cut Protection

A9 cut-resistant materials are strategically placed where skate-blade injuries are most likely to occur, delivering maximum protection while preserving flexibility and range of motion.

Protection is engineered into the fabric itself integrated seamlessly, not layered on so performance and mobility are never compromised.

Why A9 Matters

A9 represents the highest level of cut resistance under ANSI standardized testing providing measurable protection against skate-blade lacerations.

Powered by ASPIDA®, our proprietary A9 cut-protection fabric engineered for maximum defense against skate-blade contact without compromising fit, comfort, or performance.

Designed for Skate-Blade Cut Protection

Bonderkage fabrics are engineered to resist cuts and slicing contact from skate blades. They are not designed to be stab-proof or protect against puncture forces.

Protection guided by real-world injury data.

TARGETED PROTECTION ZONES

Reinforced cut-resistant coverage is strategically placed in high-risk areas such as the wrist, Achilles, calf, and neck where skate-blade injuries most commonly occur. Protection is added only where it’s needed, maintaining comfort, mobility, and performance.

Injury data, athlete movement, real-world use cases.

From research to production, every decision follows the same system logic.

1. Discover & Define

We analyze injury data, movement patterns, and game situations to identify where protection is needed most by position, level of play, and style of movement.

2. Design & Engineer

Base layers, A9 cut-resistant materials, and impact zones are engineered as a system balancing protection, mobility, and comfort without overbuilding.

3. Test & Validate

Products are tested against recognized safety standards and validated in real-world conditions to ensure consistent, repeatable performance on the ice.

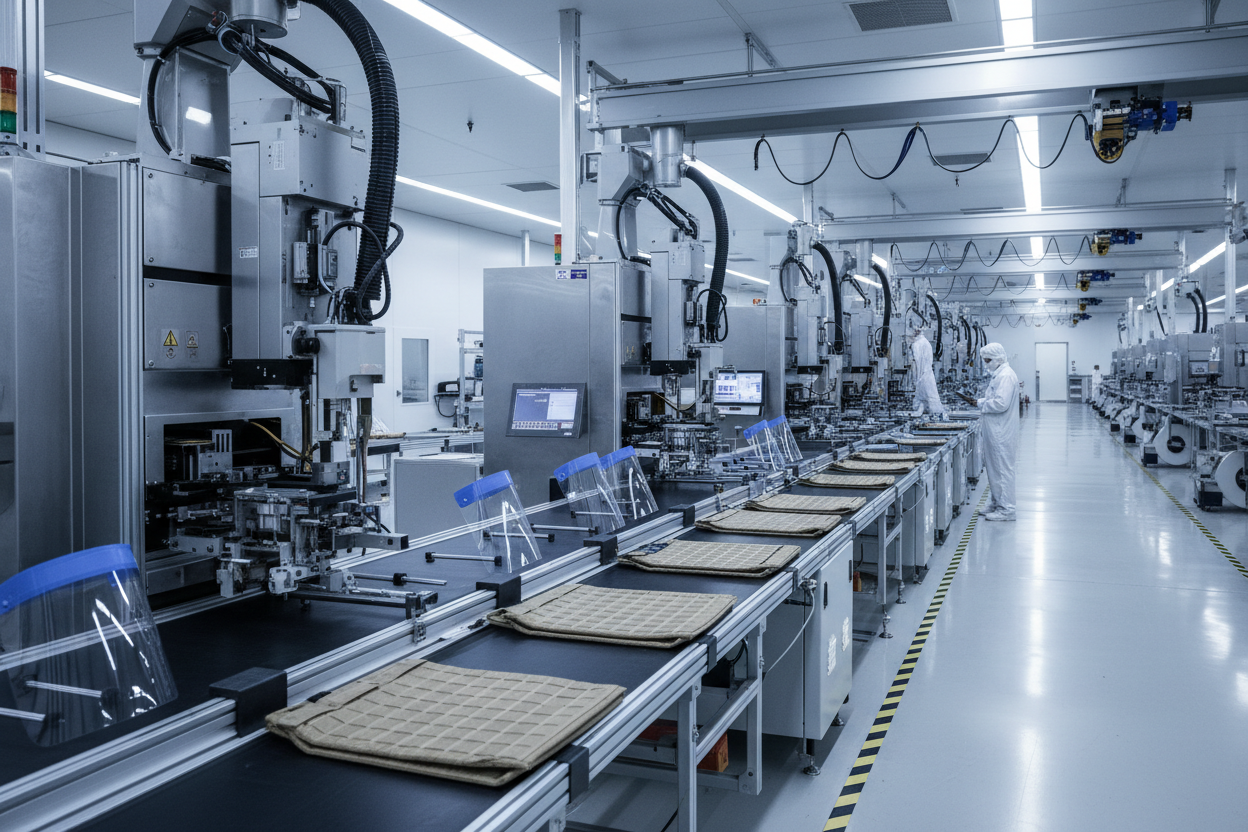

4. Manufacture & Scale

Controlled manufacturing processes and quality checks ensure every production run meets the same performance, fit, and durability standards at scale.

Tested. Trusted. Proven.

Manufacturing & Compliance

Recognized by Governing & Industry Organizations

See the System in Action

See how the system comes together across our product line.